In today’s world, with the rapid growth of industries and the need for effective and safe packaging, industrial stretch film has become one of the key tools in packaging and transportation processes. Stretch films, as elastic plastic strips, are widely used in various industries including food, pharmaceutical, and manufacturing. Due to their unique properties, such as elasticity, transparency, and resistance to external factors, these films help to package goods and prevent them from being damaged. In this article from Polypars Tehran, we will examine the features, applications, advantages, disadvantages, and future trends of industrial stretch film and analyze its importance in industrial and commercial processes.

Definition of Industrial Stretch Film

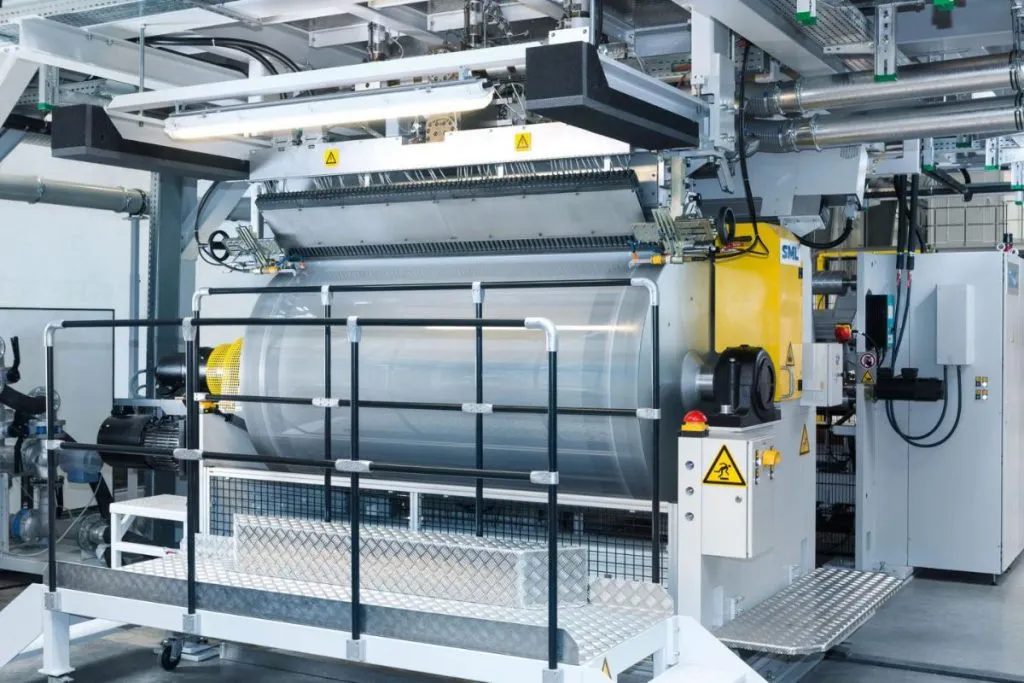

Industrial stretch film refers to a type of elastic plastic that is used to package and protect goods during transportation and storage. These films are usually made of polyethylene and, due to their high elasticity, can hold goods together well and prevent them from moving. Industrial stretch films are usually available in two types: manual and automatic.

Types of Industrial Stretch Film

Manual stretch films are typically used in situations where the load volume is small and quick packaging is required. These types of films are easily handled and used by the user. On the other hand, automatic stretch films are connected to complex packaging systems and automatically package goods. These systems are widely used in production and warehousing lines due to their high speed and accuracy in packaging.

Features of Industrial Stretch Film

Industrial stretch films have special features that distinguish them from other packaging materials. One of these features is high elasticity. These films can be stretched to a great extent and take the shape of the goods, so as to provide strong and safe packaging.

The transparency of stretch film is another important feature. This feature allows users to easily view the contents of the package. This is very efficient in warehousing and distribution processes, as it allows for quick product identification.

Other features of stretch films include resistance to moisture and contamination. These films effectively protect goods from external factors and help maintain the quality and safety of products. In addition, stretch films are usually light and compact, which helps reduce transportation and storage costs.

Industrial Stretch Film Applications

Industrial stretch films have many applications in various industries. In the food industry, these films are used as an effective solution for packaging food. Packaging fruits, vegetables, meat and other food products with stretch film prevents them from spoiling and contamination and maintains freshness and quality.

In the pharmaceutical industry, stretch films are known as a vital tool in packaging medicines and health products. These films help prevent contamination and maintain the hygienic conditions of medicines, so that the medicines are stored in proper conditions and maintain their properties.

In manufacturing industries, industrial stretch films help to package finished products and move them to warehouses or distribution centers. These tools allow manufacturers to move their goods in an orderly and safe manner and prevent them from being damaged.

In the field of stores and retail, stretch films are used as a tool for packaging goods and facilitating the purchasing and transportation process. These films allow customers to easily carry the purchased goods and prevent them from being damaged.

Benefits of Industrial Stretch Film

Industrial stretch films have several benefits that help improve efficiency and reduce costs in various industries. One of these benefits is increasing the speed of the packaging process. By using stretch film, workers can package and move loads faster, which helps increase productivity.

Reducing costs is also another benefit of this tool. Due to the reduced need for manpower and increased speed in processes, companies’ operating costs are reduced. Also, tightly packaging goods using stretch film helps reduce the risk of damage and destruction of goods, which also leads to reduced costs.

Industrial stretch film also helps maintain the quality of goods. With proper packaging and protection of goods from external factors, the risk of spoilage and contamination is minimized. This feature is especially important in the food and pharmaceutical industries.

Increased packaging accuracy is another advantage of stretch films. These films can accurately package and prevent human errors. This helps reduce waste and improve product quality.

Disadvantages of Industrial Stretch Film

Despite its many advantages, industrial stretch film also has disadvantages that should be considered. One of these disadvantages is the need for special equipment to use automatic films. Some companies may not have access to the appropriate equipment to use automatic stretch films, which can lead to restrictions in use.

In addition, if stretch film is used incorrectly, goods may not be packaged correctly, which can lead to damage. Therefore, training employees in the correct use of these films is of great importance.

Also, stretch films are usually produced from plastic materials that harm the environment. As a result, it is of particular importance to pay attention to environmental issues and use recyclable materials in the production of stretch films.

Future Trends in Industrial Stretch Film

Given the growing trend of industries and the increasing need for fast and safe packaging and transportation of goods, it is predicted that the use of industrial stretch film will increase in the future. New technologies and scientific advances in the field of packaging film production can help improve the performance of these materials and increase their efficiency.

In addition, given the increasing attention to environmental issues, it is expected that manufacturers will move towards the use of recyclable and environmentally friendly materials. This can help reduce the environmental damage caused by the use of non-recyclable plastics.

Attention to technological innovations can also help improve the quality and efficiency of industrial stretch film. For example, the use of nanotechnology can help increase the durability and resistance of these films to external factors, and therefore, improve the quality of packaging.

Conclusion

Industrial stretch film is an efficient and essential tool in today’s world that helps improve warehousing and transportation processes. Considering the unique features and benefits of this tool, it can be said that the use of stretch films not only helps to increase efficiency and reduce costs, but also helps to maintain the quality and safety of goods.

However, challenges such as the need for appropriate equipment and environmental issues must also be considered. Ultimately, by choosing and using industrial stretch film correctly, businesses can improve their performance and increase customer satisfaction. The future of this technology seems bright and it is expected that with further developments, industrial stretch film will become a key tool in various industries.