Packaging is a vital aspect of any business that has a great impact on the quality of products and customer experience. In the meantime, colored shrink nylon as a new tool in the packaging industry has attracted the attention of many manufacturers and distributors. This type of nylon, with its special features, not only helps protect goods, but also adds to the visual appeal of products. In this article from Polypars Tehran, we will examine the features, applications, advantages and disadvantages of colored shrink nylon and analyze the future trends of this technology.

Definition of colored shrink nylon

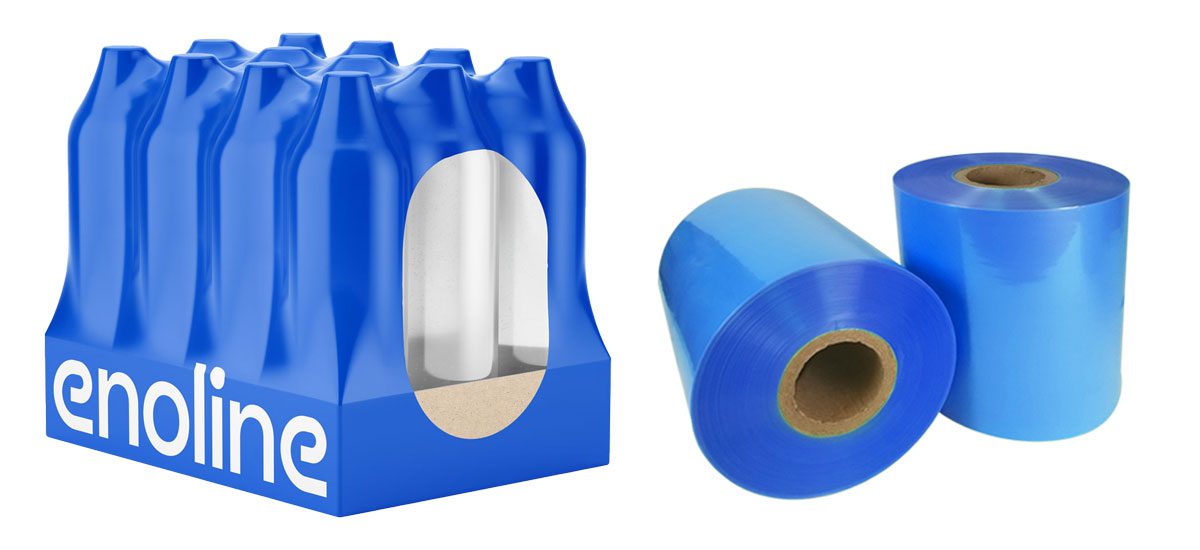

Colored shrink nylon is a type of plastic film that is produced from various polymers such as polyethylene or polyolefin. Due to their special features, these nylons automatically stick around the goods after being exposed to heat and pack them tightly. The variety of colors of these nylons allows manufacturers to create attractive and distinctive packaging that can be effective in attracting customers and increasing sales.

Features of colored shrinking nylon

Colored shrinking nylon has special properties that distinguish it from other packaging materials, some of the most important of which are:

Shrinkage property

One of the key properties of shrinking nylon is its shrinkage property. This property allows nylon to shrink around goods and take their shape after being exposed to heat. This shrinkage creates a strong and secure package that prevents damage to the goods.

Transparency and color

Colored shrinking nylon can add more appeal to packaging due to its variety of colors. This feature allows manufacturers to create unique packaging that can be effective in attracting customer attention and increasing sales. Different colors can help to better identify products and create differentiation in the market.

Resistance to external factors

Colored shrink nylon usually has high resistance to tearing, punctures and other external factors. This feature prevents the nylon from being damaged during transportation and protects the goods well. Also, these nylons are usually waterproof and dustproof, which helps maintain the quality and safety of the goods.

Printability

The ability to print on colored shrink nylon is another important feature. This allows manufacturers to easily print product information, such as brand name, expiration date and contents, on the nylon. This feature helps to improve product identification and attract customers.

Applications of Colored Shrink Nylon

Colored Shrink Nylon has a wide range of applications in various industries, which we will describe and review below:

Food Industry

In the food industry, colored shrink nylon is used as an effective solution for packaging food products. These nylons help maintain the freshness and quality of food products and prevent them from spoiling and contamination. Packaging fruits, vegetables, and other food products using colored shrink nylon prevents moisture and contamination from entering the package.

Pharmaceutical Industry

In the pharmaceutical industry, colored shrink nylon is used as a vital tool in packaging medicines and health products. These nylons help prevent contamination and maintain the hygienic conditions of medicines and prevent them from breaking and being damaged. Tight packaging of medicines with colored shrink nylon also helps maintain their quality.

Manufacturing Industries

In the manufacturing industries, colored shrink wrap helps to package finished products and transport them to warehouses or distribution centers. These tools allow manufacturers to move their goods in an orderly and safe manner and prevent them from being damaged. Packaging with shrink wrap also helps to reduce warehousing costs.

Retail

In the retail sector, colored shrink wrap is used as a tool to package goods and facilitate the purchasing and transportation process. These wraps allow customers to easily carry purchased goods and prevent them from being damaged. Also, packaging with colored shrink wrap helps to maintain the quality and freshness of products and gains customer trust.

Benefits of Colored Shrink Nylon

Colored shrink nylon has several benefits that help improve efficiency and reduce costs in various industries, some of the most important of these benefits are:

Increase visual appeal

The use of colored shrink nylon helps to visually appeal the packaging. Different colors can attract the attention of customers and, as a result, increase the likelihood of purchase. This feature is especially important in competitive markets where there are many similar products.

Effective protection of goods

Colored shrink nylon protects goods from physical damage and contamination due to its high shrinkage and resistance properties. This helps maintain the quality and safety of products and prevents financial losses due to damage to goods.

Reduce packaging costs

The use of colored shrink nylon can help reduce packaging costs. These nylons pack goods quickly and easily and require less manpower. Also, given the low production costs of shrink nylon, this packaging method can be cost-effective.

Increase in speed of operation

The use of colored shrink nylon helps to speed up the packaging and distribution processes. These nylons are easily and quickly wrapped around goods, which reduces the time spent on packaging. This feature helps to increase productivity and reduce the time required to move goods.

Recyclability

Many colored shrink nylons are produced from recyclable materials. This helps to reduce the environmental impact of using non-recyclable plastics and allows manufacturers to provide better services to their customers while respecting environmental principles.

Challenges of Colored Shrink Nylon

Despite its many advantages, colored shrink nylon also has disadvantages that need to be considered:

Requirement of Special Equipment

One of the challenges of shrink nylon is the need for special equipment to use this type of nylon. Some companies may not have access to the appropriate equipment to use shrink nylon, which can lead to limitations in use.

Environmental Hazards

Shrink nylon is usually produced from plastic materials that harm the environment. As a result, paying attention to environmental issues and using recyclable materials in the production of shrink nylon is of particular importance. This is especially important in this era when attention to environmental issues has increased.

Need for Employee Training

If shrink nylon is used incorrectly, goods may not be packaged correctly, which can lead to damage. Therefore, training employees in the proper use of these nylons is of great importance. Lack of awareness of proper packaging methods can cause problems in the supply chain.

Future Trends of Colored Shrink Nylon

Given the growing trend of industries and the increasing need for fast and safe packaging and transportation of goods, it is predicted that the use of colored shrink nylon will increase in the future. New technologies and scientific advances in the field of packaging film production can help improve the performance of these materials and increase their efficiency.

Focus on Recyclable Materials

Given the increasing attention to environmental issues, it is expected that manufacturers will move towards the use of recyclable and environmentally friendly materials. This can help reduce the environmental damage caused by the use of non-recyclable plastics and reduce the negative impacts on the environment.

Technological Innovations

Paying attention to technological innovations can also help improve the quality and efficiency of colored shrink nylon. The use of nano technologies can help increase the durability and resistance of these nylons to external factors, and therefore, lead to improved packaging quality.